-

Discussion of product specifications

- Our domestic sales representatives provide one-stop services

- We will cooperate with domestic designers to review the specifications

- All discussions regarding the handling of products between overseas bases (for products delivered from our overseas location to the customer's overseas location) can be conducted in Japan.

-

Design and proposal

- Our products are designed to meet customer requirements based on the details of the discussion

- We utilize our technical expertise to propose methods for cost reduction and quality improvement

- We propose solutions that achieve consistent quality and low cost, which can only be realized through a specialized press manufacturer with capabilities for an integrated production system and overseas manufacturing bases.

-

Prototype mold production

and trial press runs- We will produce trial molds based on the design as necessary

- We provide the option to manufacture the prototypes overseas upon request

- It is also possible to run the prototype in Japan and manage the mass production overseas

- Trial test runs using prototype molds

- Prototype production using punch presses

- Review of issues and identification of potential problems during mass production

- Multiple meetings and discussions to prepare for the mass production process

-

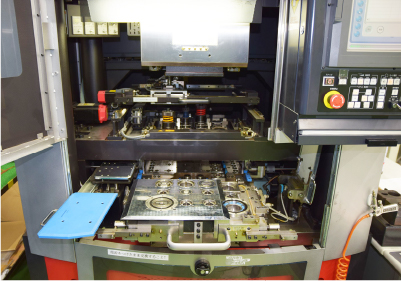

Mass production of molds

- High-performance mold production with a focus on productivity that can only be achieved by an integrated manufacturing system.

(We pursue the perfect combination of press metal and resin molding dies.)- We also have the means to support customers who are considering to transfer the production overseas.

- We can manufacture highly durable molds according to the customers' requests

-

Mass production processing

- Utilizing domestic and overseas bases to offer the optimal production location for the customer

- Pressing and resin molding available in all factories

- We can produce molds manufactured by other companies at our domestic and overseas bases.

-

Plating

- Lead frames: Silver plating (Tsugaru Factory and the Philippines)

- Connectors: Gold plating (Tsugaru Factory, the Philippines, and China) and Tin plating (the Philippines) We will cooperate with various plating manufacturers outside of our own plating line according to the requests of our customers.

-

Resin molding

- Fine, high-quality injection molding for LED lead frames, sensor components, and narrow pitch connectors

-

Assembly

- Especially for connectors, the scope of our capabilities ranges from supplying the components to the OEM of finished products.

- Integrated production from design to manufacturing can be handled in Japan and overseas

-

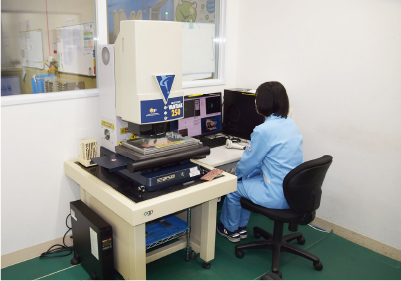

Quality control inspection

and verification- The quality of overseas products are controlled with the same level of standards as those produced in Japan

- All of our factories are ISO 9001 certified

- We have an extensive track record of supplying products for automotive devices, which have particularly strict quality standards

- We handle various inspections and verifications upon request

- Measurements and analyses may be conducted with 3D measuring machines, laser microscopes, SEM, FT-IR, and other high-performance instruments.

BUSINESS